A recent project in the Texas Panhandle shows the value digital technologies have to offer Underbalanced Coiled Tubing Drilling operations by Adam Miszewski, Global Operations Manager of AnTech Ltd.

DATA-DRIVEN, UNDERBALANCED CTD IMPROVES REAL-TIME DECISION-MAKING

1st March 2019

Underbalanced Coiled Tubing Drilling (UBCTD) offers operators a way to capture significant extra value out of known reserves and makes maximising returns from declining fields a viable proposition. Indeed, when applied correctly, such technologies have been shown to deliver increased production rates at reduced cost when compared to traditional methods.

The technology is relatively new. Yet, as with all things these days, its newness has not stopped developments continuing apace. By combining the capabilities of UBCTD and the capabilities of digital technologies, another level of productivity, operational and cost effectiveness can be achieved.

The capabilities of UBCTD can be seen in a recent project led by AnTech in the Texas Panhandle. Specialist contractors were utilised for each major component of the project and tightly integrated using project management best practices and digital technologies. As such, it can be said to represent the state-of-the-art not only in the region but across the industry as a whole.

It is helpful to first provide an overview of the project and what it hoped to achieve.

The project was a two well re-entry campaign in the Texas Panhandle and was part of a wider campaign to revitalise a field that had been producing for many years. The overarching aim of the campaign was to intercept fractures and access untapped reserves to boost production. Underbalanced drilling was seen as the best way to increase production from the field because it is known that preventing a formation from becoming overbalanced at any time can have a significant impact on subsequent production. Secondary reasons to drill the wells using UBCTD were stable underbalanced conditions, which is especially important when working with two-phase flow, and reservoir characterization while drilling allow accurate water shut off.

In the case of the project under consideration here, the two wells were primarily gas producers, with condensate and water also being produced. UBCTD was seen as the best way to drill the reservoir underbalanced because it provided continuous stable underbalanced bottom hole pressure, as well as fast, safe and effective operation in two phase flow.

Project overview

Aggregating digital data was critical for project success

In order to maximise the success of the first drilling campaign on the two wells, a great deal of time and effort was given to planning the operation. The operator was determined to put the right time and resources into the planning phase prior to execution; setting the whole operation up for success.

In the early stages of the project, it was decided to take advantage of digital technologies in the form of wellsite data acquisition, offsite support for data analysis and downhole sensors by aggregating the data from all the parties involved. By doing this, all parties would be able to have a complete picture of what was happening on the wellsite and the speed of decision making could thus be improved.

There was another reason for aggregating the data in real time. This was because RockSense, AnTech’s proprietary synthetic porosity algorithm, was to be used on the project and this required a complete real time data picture. RockSense has the ability to distinguish between different formations by combining downhole and surface data in real time to give an at-bit measurement of porosity. It offers two considerable advantages over traditional geosteering techniques. First, because wired telemetry has a high data rate, multiple measurements can be made for every foot drilled and operators can gain inch-level resolution. Second, because the data delivered are representative of conditions at the bit – not 20-25ft behind it – the driller can deliver an optimally placed wellbore, with more feet drilled in the target zone.

However, for data aggregation to be achieved in real time, a very much more collaborative approach from the very earliest stages of the project was needed.

It is perhaps worthwhile briefly touching on why this was the case. There are typically four principal parties in a UBCTD campaign: the directional downhole tools provider, the coiled tubing service company, the underbalanced drilling fluids package and the operator. Each service company uses their own data acquisition system (DAS). This means an incomplete picture is available to any party at any given time and there are delays in decision making while data from the other parties is requested, collated and analysed.

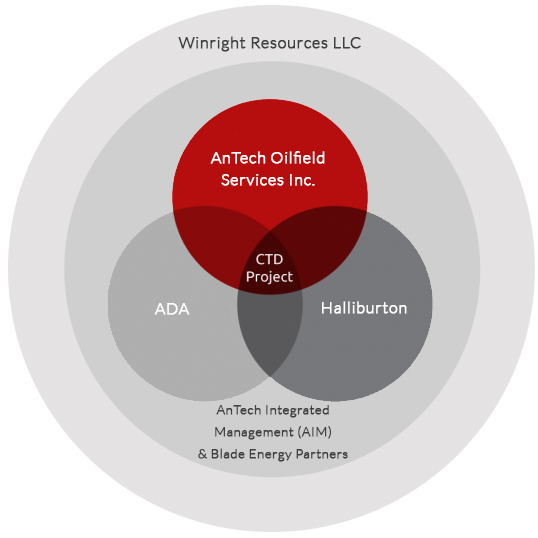

The role of aggregating the data was taken on by AnTech, the directional service provider. AnTech also provided pre-job engineering, pre-job project management, downhole equipment and data aggregation. Halliburton provided CT unit and pumps, ADA provided the fluids separation package and Blade Energy Partners provided pre-job engineering, Wellsite Supervision/ Project management on-site. (See Figure 1.) To enable the CT unit to run e-coil, AnTech provided the conversion kit to convert the rig to e-line (slip ring collector, collector bulkhead), work that was done well in advance of arriving at the wellsite.

To view the full article, please visit: World Oil or contact us

Figure 1: The interaction of service companies for the UBCTD campaign

+44 1392 933 100 | +1 800-868-1562